Costing

Of course, one of the most important things when planning on creating a new product is cost. In terms of sustainability, it is a well known fact that sustainable products are higher in costs and it may be a small deterrent to consumers. However, once you educate the public on why the costs are higher, the benefits will seem more beneficial then the costs. When you look at costs, again in terms of sustainability, the following factors attribute to higher costs:

- certification of product being sustainable

- alternative means of maintaining raw material

- fair trade labor

I wanted to test out 3 situations of what would be the ideal situation in producing my product and what would be cheaper for me.

- certification of product being sustainable

- alternative means of maintaining raw material

- fair trade labor

I wanted to test out 3 situations of what would be the ideal situation in producing my product and what would be cheaper for me.

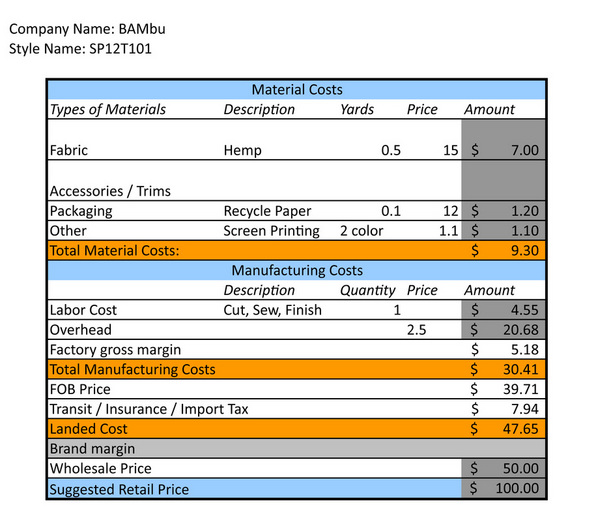

Hemp and Screen Printing

The first situation I picked was using

Hemp fabric and putting a 2-color screen

print design on it.

Surprisingly, I found that Hemp was the most expensive of the three different fabrics

that I had chosen. Why this surprised me is because Hemp is a faster producer than Organic Cotton and doesn't need pesticides or any other chemicals for maintenance, which should reduce costs, however; it costs a lot more. Even with this price of $15 a yard, this was the price at buying a minimum of 500 yards. To buy at individual yards, would be $18.

I chose Screen Printing as an option of design because it is practiced often on tees. It came out to be cheaper than the other fabrics, however; the effects on the environment is not worth it in the long run. There is a lot of water waste and toxins exposed to the environment when doing screen printing.

For labor, I kept it at fair trade value and am paying the worker based on the bundling system.

Hemp fabric and putting a 2-color screen

print design on it.

Surprisingly, I found that Hemp was the most expensive of the three different fabrics

that I had chosen. Why this surprised me is because Hemp is a faster producer than Organic Cotton and doesn't need pesticides or any other chemicals for maintenance, which should reduce costs, however; it costs a lot more. Even with this price of $15 a yard, this was the price at buying a minimum of 500 yards. To buy at individual yards, would be $18.

I chose Screen Printing as an option of design because it is practiced often on tees. It came out to be cheaper than the other fabrics, however; the effects on the environment is not worth it in the long run. There is a lot of water waste and toxins exposed to the environment when doing screen printing.

For labor, I kept it at fair trade value and am paying the worker based on the bundling system.

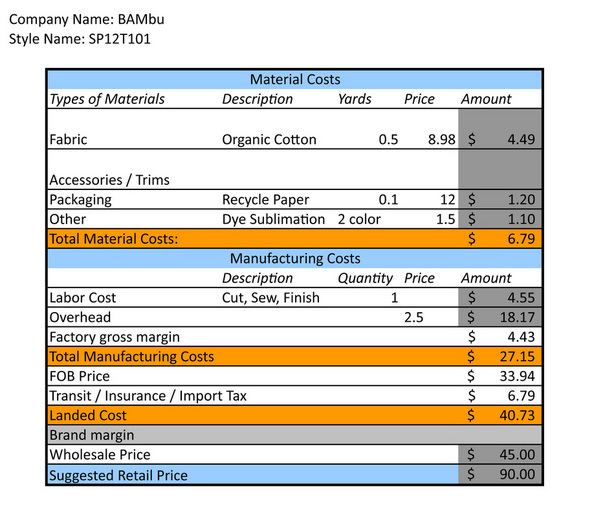

Organic Cotton and Sublimation Printing

The second situation I picked organic cotton and doing a 2-color dye sublimation print design on it.

Of all the fabrics, organic cotton was the cheapest which was another surprise to me. Of all 3 of the fabrics, organic cotton is the slowest and hardest to grow under conditions of using new pesticides or other chemicals to maintain it and the soil it's being grown from. The price is still higher than conventional cotton by at the minimum 3x the amount.

The costs of dye sublimation was a couple cents higher which I found a little bit surprising because there are more chemicals and a more tedious process to screen print than it is to sublimate.

Overall, even though screen printing is cheaper, I still wouldn't use it because I know how harmful it is to the environment and potentially to the worker, having to work with all the dyes and chemicals.

Again, I left the labor at fair trade value.

Of all the fabrics, organic cotton was the cheapest which was another surprise to me. Of all 3 of the fabrics, organic cotton is the slowest and hardest to grow under conditions of using new pesticides or other chemicals to maintain it and the soil it's being grown from. The price is still higher than conventional cotton by at the minimum 3x the amount.

The costs of dye sublimation was a couple cents higher which I found a little bit surprising because there are more chemicals and a more tedious process to screen print than it is to sublimate.

Overall, even though screen printing is cheaper, I still wouldn't use it because I know how harmful it is to the environment and potentially to the worker, having to work with all the dyes and chemicals.

Again, I left the labor at fair trade value.

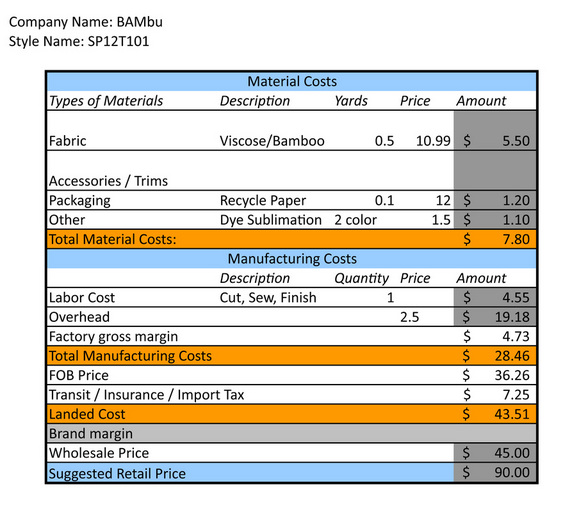

Rayon from Bamboo and Sublimation Printing

Last, the situation I picked was with Rayon from Bamboo and doing a 2-color dye sublimation print design (my original intended choice of material and finishing).

The costs of the fabric from bamboo was what I had expected. It was more expensive than cotton but cheaper than hemp. Hemp and Bamboo has the same attributes and characters as a fabric so creating rayon from this source would be a lot cheaper.

I again used dye sublimation and after totaling up the costs, it came out to be the same as if I were to use Organic Cotton. So the question is which fabric was better.

After the research I conducted a couple weeks ago, I personally think that rayon from bamboo is the better fabric. It grows faster, easier and cheaper to maintain and the production of the fabric is environmentally friendly because it uses a closed loop system.

Naturally, I kept the labor at fair trade. Obviously, if I didn't the costs would have been a lot cheaper but it would be no way sustainable because the workers wouldn't be paid fairly.

The costs of the fabric from bamboo was what I had expected. It was more expensive than cotton but cheaper than hemp. Hemp and Bamboo has the same attributes and characters as a fabric so creating rayon from this source would be a lot cheaper.

I again used dye sublimation and after totaling up the costs, it came out to be the same as if I were to use Organic Cotton. So the question is which fabric was better.

After the research I conducted a couple weeks ago, I personally think that rayon from bamboo is the better fabric. It grows faster, easier and cheaper to maintain and the production of the fabric is environmentally friendly because it uses a closed loop system.

Naturally, I kept the labor at fair trade. Obviously, if I didn't the costs would have been a lot cheaper but it would be no way sustainable because the workers wouldn't be paid fairly.

Conclusion

After doing the costs of all the situations, I can see why sustainable products are more costly. But in the long run, it's worth it to the customer to pay more because:

1. The fabrics are excellent quality. They're made without all the chemicals that can reduce the integrity of the fabric.

2. Fair labor affects the worker in a positive way. Workers who work in great conditions, are treated well and are paid fairly, will do a better job at hand which results in better quality garments.

3. It helps the environment. It may be baby steps, but reducing water waste and toxins being put into the environment will help the world slowly return to it's previous state.

I am going to stick to using rayon from bamboo and using the dye sublimation printing technique. The reason why I'm sticking to this is because I truly feel the fabric has better qualities than organic cotton. It has the same qualities as hemp, but it is way more cheaper. Also, dye sublimation is a lot more environmentally friendly than screen printing. It's only .40 more expensive, but I'm willing to pay for that cost.

1. The fabrics are excellent quality. They're made without all the chemicals that can reduce the integrity of the fabric.

2. Fair labor affects the worker in a positive way. Workers who work in great conditions, are treated well and are paid fairly, will do a better job at hand which results in better quality garments.

3. It helps the environment. It may be baby steps, but reducing water waste and toxins being put into the environment will help the world slowly return to it's previous state.

I am going to stick to using rayon from bamboo and using the dye sublimation printing technique. The reason why I'm sticking to this is because I truly feel the fabric has better qualities than organic cotton. It has the same qualities as hemp, but it is way more cheaper. Also, dye sublimation is a lot more environmentally friendly than screen printing. It's only .40 more expensive, but I'm willing to pay for that cost.